Bald facts about natural oil paint

Traditional oil paint was made primarily of linseed oil (squeezed from the seeds of flax from which we get linen) with a bit of tree resin thrown in and boiled. This effectively made an oil varnish. When pigment was added it became paint. Today there is a small-scale Swedish business (Allbäck) that sells a simpler version of that paint, just pure linseed oil, all over the world. And there is me, who makes traditional oil paint on weekends and during holidays in my wife's AGA and sells it all over the UK. Our two paints are similar in as much as they are made of natural plant products and the paint coating you apply with them should last a long time. Because recoating isn't necessary for a few extra years means these paints should repay, in pure financial terms, the extra cost and effort of using them. They are both difficult to use, for both are slow drying. The Swedish paint is slower drying; mine dries much faster but the danger of wrinkling is thereby increased. I offer just about any colour there is; the Swedes offer a dozen colours. The Swedish paint dries matt; mine dries glossy but sadly it isn't perfectly smooth like glass, it will produce a surface with tiny little bumps, unless you are extremely professional at painting. The Swedish paint is prone to develop mildew; mine is completely fungus free (there is a whole section on this at the bottom of the page). Using these paints is good for the environment and should give you something to talk (gloat) about with your friends.

Traditional oil paint was made primarily of linseed oil (squeezed from the seeds of flax from which we get linen) with a bit of tree resin thrown in and boiled. This effectively made an oil varnish. When pigment was added it became paint. Today there is a small-scale Swedish business (Allbäck) that sells a simpler version of that paint, just pure linseed oil, all over the world. And there is me, who makes traditional oil paint on weekends and during holidays in my wife's AGA and sells it all over the UK. Our two paints are similar in as much as they are made of natural plant products and the paint coating you apply with them should last a long time. Because recoating isn't necessary for a few extra years means these paints should repay, in pure financial terms, the extra cost and effort of using them. They are both difficult to use, for both are slow drying. The Swedish paint is slower drying; mine dries much faster but the danger of wrinkling is thereby increased. I offer just about any colour there is; the Swedes offer a dozen colours. The Swedish paint dries matt; mine dries glossy but sadly it isn't perfectly smooth like glass, it will produce a surface with tiny little bumps, unless you are extremely professional at painting. The Swedish paint is prone to develop mildew; mine is completely fungus free (there is a whole section on this at the bottom of the page). Using these paints is good for the environment and should give you something to talk (gloat) about with your friends.That's the short version. For those with strong constitutions, read on . . . .

everyone else should jump down to How to Use or Our Colours.

A short history of oil paints

The "oil" paintings we see hanging in galleries were not produced with primitive linseed oil paint. Expensive, quality paint in the Renaissance did contain linseed oil in abundance but it was treated (to create, for instance, "stand oil") and tree resins were being added. The tree resins came primarily from European pines and larch and made the paint harder and quicker drying.By the 19th century, the resins used had been extended to "mined" sources of ancient and even fossilised resin (amber) and from trees all over the globe. Resin from Kauri pine in New Zealand was as far from Britain as it gets. The proportion of oil to resin generally distinguished paint as "long oil" or "short oil". The latter, with higher proportions of resin, were more expensive, harder wearing and used on interiors. The former, with more oil, were cheaper, more flexible and used outdoors.

Up until the Second World War, glossy oil paint remained much as it had been for centuries. By then, however, it had been found that metal soaps acted as catalysts in the drying process. And lead, which was first added as a white pigment, proved to have all manner of beneficial side effects, making paint tougher and repelling mould growth. And it lasted a long, long time. In short, traditional oil paint was good. But industry wished to make it better. And chemists managed this by modifying the resins used in oil paint.

Linseed oil became even more important as chemistry created alkyd resin from oils. The paint dried harder and faster and thicker, which produced a more perfectly flat surface. In short, it was a much better paint. More so for the industry, perhaps, than the consumer. Excellent to use, but it had to be bought more often, for the paint didn't have the same life expectancy. In time, chemistry modified all manner of oils from which fatty acids are extracted (tree resin was now redundant) and linseed oil gave way to oil from sunflower, safflower, soya and even fish. The linking thread here is the food industry. The decline in the comparative cost of food for half a century after the last world war meant that the comparative cost of oil paint also went down.

This alkyd resin paint, which I grew up in Massachusetts simply calling "oil paint", you may know as "gloss" paint. And for good reason: oil-based paint does indeed produce the glossiest finish available. But a semi-sheen (satin or eggshell to most consumers) has reigned supreme for decades now. And satin is the hallmark finish of the plastic paints which sounded the death knell for oil paints. Latex paint, although familiar in the USA, never really found a place in the UK where acrylic paint now dominates as it does in most of the world. I first tried it in 1989. It was awful. So why did its popularity grow?

From the consumers' perspective, acrylic paint is convenient. It dries very quickly, brushes and spills are cleaned with water, and it doesn't smell. The only drawbacks when first developed were that it gave a far inferior finish and peeled off easily. Today it doesn't peel off and the finish is slightly better than it used to be, although far inferior to oil paint. However, it does rival and probably surpass alkyd resin in longevity outdoors. But, as a petrochemical product (acrylic is a plastic), it is possible that its rise is due to industrial preferences rather than those of consumers. Although new production processes can make alkyd resin into an emulsion, suspended in water, commercially the oils are heading for extinction.

Why should you use natural plant oil paint?

First and foremost, because it is good for the planet. It is made from natural materials. Far less energy is expended to produce it than conventional paints and it is made without fossil fuels. Linseed oil paints scarcely contribute to global warming compared to conventional paints. And here is an interesting fact. Britain was once a large producer of linseed oil. Today there is no industrial production. But Britain does convert petroleum into plastic paint.You should use natural oil paint because it lasts longer than conventional exterior paints, easily lasting ten years (fifteen with some upkeep). While it is more expensive to buy, it works out cheaper in the long run, especially if scaffolding is required.

Alas, there are also reasons for not using these plant oil paints. They aren't as easy to use as conventional paints, especially with their slow drying. The surface coating they produce, while longer lasting, isn't as tough (the elasticity is part of the key to its longevity), so they scratch more easily.

How do you use my traditional oil paint?

Assuming that you have supressed your doubts and decided to try my home-cooked paint, how do you go about using it? Let's skip the preparation for now and give a condensed version of practical advice.In short, apply very thinly and go back over painted surfaces looking for dribbles and pooling of the paint and work them out. Leave two days or more between coats. Apply two coats, sometimes three depending on the colour and the original surface preparation.

Our paint is thinner than conventional paints and thus drips more. It has to be painted on very thinly or it wrinkles when dry, so being thin is not a bad thing, except you really have to watch for dribbles and pooling in corners. By painting it very thinly, the paint also dries in a day, which is a rare thing for linseed oil paint. But dry to the touch is not the same thing as dry through and through. So leaving days between coats is best.

It needs more stirring than conventional paint because the pigments sink to the bottom. And when the first coat goes on, it doesn't look anything like as good as you probably hoped it would because the colour is not fully opaque and that is because the natural oils don't hold as much pigment as conventional paints.

When stored, it will form a thin surface skin in the tin faster than you ever expected. With care, it can be removed without breaking up and contaminating the paint. If small broken bits of skin do contaminate the paint, a sieve is usually provided with the paint so you don't have to search for some old stockings.

There will be tiny bumps in the gloss finish, largely due to the very active way the surface of the paint dries. It will creep over the minutes particle of dust that land on the painted surface. A very light sanding is possible between coats. But the coated surface is very soft for weeks, so easy does it.

Because of its imperfections and lack of toughness, we recommend the paint for exterior use only.

For more details on using our paint go to our page on the subject.

Available colours?

Theoretically, all colours are available. The colour comes from pigments added to the oil and resin and a rainbow of pigments are commercially available. Some pigments are natural, meaning they are dug from the ground, especially the yellows and browns and reddish versions thereof (traditional sienna, burnt umber, raw ochre, yellow ochre, etc). Many of the pigments are not natural. These inorganic, synthetic colours are created by applying various processes to commonplace metals. These pigments are often largely made of industrial waste, so those monitoring the ecological credentials of paints commend the synthetic colours as even more environmentally friendly than natural pigments, which often involve a great deal of energy in the course of mining.

Many of the pigments are not natural. These inorganic, synthetic colours are created by applying various processes to commonplace metals. These pigments are often largely made of industrial waste, so those monitoring the ecological credentials of paints commend the synthetic colours as even more environmentally friendly than natural pigments, which often involve a great deal of energy in the course of mining.I had planned to create my own "range" of colours but the need has not arisen since my paint is not stocked by any retailer. My simple plan of single pigment colours has also failed to be realised because no one wants Prussian Blue, Brown Ochre, Chrome Yellow, or Green 15. Customers want Elephant's Breath and Mouse's Back and Smoking Slippers Green. In other words, off whites and neutral pales.

By default, my standard colours are now all the colours I have made for customers over the last two years. These are the colours for which I have a formula which allows me to mix them again and again. The bulk of the requested colours come from the brochures of Farrow and Ball. I can also match any Holkham colour, which is often requested when people come to freshen the Swedish linseed oil paint that they applied half a dozen years ago. Otherwise I try to steer customers to British Standard (BS) colours and European Standard (RAL) colours. Here is the list of colours with a formula as stands:

Linseed Paint Co: White, Black, Venetian Red, Plum,

Farrow & Ball: Clunch, Lime White, String, Pavilion Gray, French Gray, Blue Gray, Pigeon, Old White, Dorset Cream, Cooking Apple Green, Ball Green, Vert de Terre, Lichen, Green Blue, Dix Blue, Parma Gray, Light Blue, almost any other can be matched.

Holkham: Barley White, Parchment, Buttermilk, Brick Red, Lichen, Wild Sage, Spruce Green, Linseed Blue, Chocolate

British Standard: 04D45 (dark red, Dulux's Monarch, Johnstone's Burgundy), 12B25 (Historic Scotland Green), 12B29 (dark green, Juniper), 18C39 (Dulux's Dolphin)

European Standard: Leaf Green (RAL 6002), Middle Grass Green (RAL 6010), Fern (RAL 6025)

Why does Ross hate white?

Nothing in our paint is less environmentally friendly than Titanium Dioxide, or white. It is the only pigment that is monitored for environmental creditation. Bad for the planet, it is almost as if karma punishes me when I come to use it. TiO2 does not have good opacity. White and off-whites do not give solid colour coverage. Let me spell this out in black and white. Black is the most solid colour pigment with excellent opaque qualities. Two coats of black will produce a completely black coat; three coats of white, by contrast, will almost be a solid white. At this point, four times more white pigment will have been applied to the surface than black pigment and the black will look better. 400% more white is required, and it is the only pigment colour that is environmentally unfriendly. And even once you have painted your windows white, the linseed oil will yellow over the next year or two sufficiently to turn the white into cream! Karma indeed.Every other colour under the sun

Mixing pigments to achieve a desired colour is not without problems. In fact, so many that there is no point to discussing them here. Our page devoted entirely to colours will give you more information. Here let me simply say that you and I cannot communicate colours through computer monitors. Mine is so far from true that it simply cannot be trusted. But I can show you a sample series I made when a customer wanted a certain shade of blue. And I can say that the colour match will be closer than the typical neighbouring colour on a paint manufacturer's colour chart. If you want Farrow & Ball's Dead Salmon, the colour I make might be closer to Smoked Trout. But a deceased member of the Salmonidae family it certainly will be. This mixing service is free from me, but costs a pretty penny from my linseed rivals.

Some background on commercially available linseed oil paints

Natural oils have quite different characteristics compared to the gloss alkyd resin (oil) paints you will be familiar with. Modern paints go on thick and the liquid they are dissolved in (their solvent), whether white spirit or water, evaporates leaving a thinner film. Natural oils go on thin and get thicker as they dry! There is little if any solvents, but as the oil oxidises, it captures oxygen from the air, thickening until solid.The Swedish company, Allbäck makes linseed oil paint. It has been sold in the UK for over a decade under the name of Holkham Paint. In 2012 it changed its name to Linseed Paint and Wax Co. Since that is almost exactly our name, I take it they tried to confuse buyers. Their product is almost pure linseed oil, with a tiny amount of metal driers added. It takes longer to dry than our own and is not free from the scourge of mildew. They offer to sell zinc oxide which you can add to kill fungus. Ottosson also makes linseed oil paint that appears to be of almost identical composition to Allbäck, their zinc oxide is already added. The German company Aglaia sells a natural oil paint, which is a concoction of linseed and other plant oils and terpenes (natural solvents) and metal driers. It is more industrially manufactured and it is not clear how much chemical modification of the oils occurs. My paint is much more a "traditional" paint rather than linseed oil paint. The key is that I add resin to the oil. For the moment, we simply use resin from pine trees, the sticky stuff that oozes from the tree that people often call sap (although technically that's incorrect). Traditionally, only the poor paints got pine resin. The best paints got fossil resins (amber) or exotic resins, such as semi-fossilised kauri pine resin from New Zealand. The resin adds a bit of hardness to the paint and it speeds up the drying process, slightly. And while drying, it makes the paint sticky. But that stickiness is good for adhesion, so our paint is better at sticking to a previously painted surface than pure linseed oil. Also, pine trees exude this resin when damaged. The role of resin is to seal the wound and prevent infections. It kills. It is a disinfectant. That's why so many cleaning products have that pine fresh smell.

Because of the thickness of our oil and resin (almost the consistency of tar), we add small quantities of natural solvent extracted from grapefruit and orange peel. It is used in small quantities (not more than 15% by weight and generally under 10%) and should pose no health hazard (some people seem to fear hydrocarbons as if they were lethal -- see our page on solvents for more information). Not to people at least, but certainly to mildew.

Because of the thickness of our oil and resin (almost the consistency of tar), we add small quantities of natural solvent extracted from grapefruit and orange peel. It is used in small quantities (not more than 15% by weight and generally under 10%) and should pose no health hazard (some people seem to fear hydrocarbons as if they were lethal -- see our page on solvents for more information). Not to people at least, but certainly to mildew.

My paint spells death to mildew

For those of you not familiar with linseed oil paint, this might seem an awfully strange heading to get such prominence. But the simple fact is, linseed oil is notorious for growing fungus (and since cold-pressed linseed oil is sold as a salad dressing, this is perhaps not so surprising: what would you expect to find on your window sill if you painted it with olive oil and balsamic vineagar?). If you search this phenomenon on the internet, you will find many strange claims and stranger people. The strangest are the fine artists who make their own oil paints and subject flax seed oil to all manner of secret traditional cleansing processes in an attempt to recreate the paints of the ancient masters. The goal is to create a paint (and thus a painting) that will easily last a millenium, presumably because they believe their own daubs are worth it. You will also find the utterly ignorant who assume that all products based on linseed oil will encourage mildew and thus eschew alkyd resin varnishes in favour of hateful acrylics for fear of miniature mushrooms. The cruel irony is, of course, that you'll never find a mould growing inside a tin on the liquid surface of an alkyd resin varnish, but you will find it on acrylic varnishes that have been sitting about for many years. Ignorance may be bliss, but it is also stupid.Mould will grow on linseed oil before it hardens if conditions are right. Linseed oil is or has been used extensively in the world of log cabins. And log cabins tend, geographically, to be most common in cool areas of higher rainfall (north American west coast, Scotland, Scandinavia, Estonia). Trawl the log cabin forums and you will find discussions about the curse of blackness forming on logs. While Allbäck paints have claimed that the dark fungal menace is no match for their especially good strains of flax, timber treated with their paint does sometimes come over all mouldy. And because of complaints (which they rarely answer), they have started offering zinc oxide at an additional cost when purchasing their paint. Whatever the underlying problems the timber may have, whatever the local environmental situation, there is no escaping this: when mould grows on surfaces treated with linseed oil, the fungus is eating the oil.

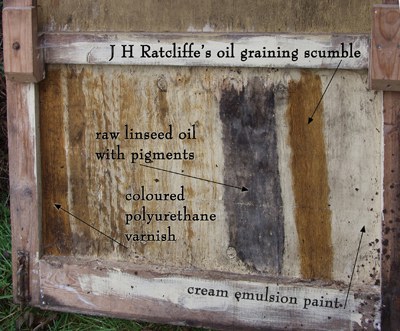

Here is a photograph of the inside of my workshop back door. I painted a section with cream emulsion, then sought to create a grain effect by overpainting with scumble. The reason for this experiment was to find the easiest and cheapest way of painting faux oak grain, which is how we treat white radiators. Over the radiator goes one of our Arts & Crafts radiator cabinets. On the door, I used a coloured polyurethane varnish (which isn't streaky enough to create grain-like patterns), Ratcliffe's oil scumble, which we still use for this graining process, although now no longer available, having been replaced by a rubbish water-based product, and my own linseed oil and pigment mixture. This was before I started making linseed oil paint, but represents some early steps towards it. Despite the horrific damp – this door gets lashed by rain – neither of the conventional products induced any fungal growth. The section treated with linseed oil turned black within a year.

Here is a photograph of the inside of my workshop back door. I painted a section with cream emulsion, then sought to create a grain effect by overpainting with scumble. The reason for this experiment was to find the easiest and cheapest way of painting faux oak grain, which is how we treat white radiators. Over the radiator goes one of our Arts & Crafts radiator cabinets. On the door, I used a coloured polyurethane varnish (which isn't streaky enough to create grain-like patterns), Ratcliffe's oil scumble, which we still use for this graining process, although now no longer available, having been replaced by a rubbish water-based product, and my own linseed oil and pigment mixture. This was before I started making linseed oil paint, but represents some early steps towards it. Despite the horrific damp – this door gets lashed by rain – neither of the conventional products induced any fungal growth. The section treated with linseed oil turned black within a year.

When does the woodwork need repainting?

In Scotland, the conventional wisdom for architectural maintenance was that woodwork should be repainted with gloss "oil" paint every five years (not that many bother to). Conventional wisdom on linseed oil paint websites is that it lasts 15 years without further treatment. Moreover, it then only needs repainted with a coat of linseed oil, which costs very little. With our inclusion of wood oil, we are aiming for a quarter of a century, a lifespan quoted by some traditional Swedish builder/painters. But the success or failure of painted surfaces depends on many variables quite independent of the paint itself, primarily the surface taking the paint (raw wood, planed timber, and what type of wood at that and its ambient moisture content, old paint, linseed putty, silicone, and its exposure to sunlight). Like any other paint, linseed paints on north-east facing surfaces, out of the sun and rain, do better than paint on south-west facing surfaces (sorry for not taking you antipodeans into consideration here). Like any other paint, linseed paints tend to fail on timbers that get very wet and have an average moisture content well above 15%, as window sills often do. And like any other paint, linseed paint does better on rough, "off-saw" timber than on a planed, smooth surface. Indeed, the paint will do so much better that it is well worth specifying rough unplaned timber if you are building anew. This will add years and years onto the repainting cycle.Traditional gloss oil paints and modern acrylic paints both suffer structural disintegration primarily from a pounding from ultraviolet light. Linseed oil paint appears to suffer structural disintegration primarily from organic and inorganic decomposition. Because mould and pollution, which are in turn affected by moisture and local geography, play an even larger part in the long-term disintegration of linseed oil paint than ultraviolet light, it is harder to predict how long its life expectancy is in your specific situation.

So, is it worth it?

The paint is expensive. The painting programme will take longer and is more drawn out than usual. That makes the labour expensive too. But once on, there is little and only inexpensive maintenance for the next three or four decades. By that time, the "maintenance free" uPVC windows next door will probably have been ripped out, plastic or metal parts having failed and being impossible to maintain. So, yes, in the long term it is value for money. But it also offers things that can't be valued in monetary terms: a good environmental conscience, a sense of standing apart from the crowd, and an excellent talking point at your next dinner party.Who are we?

We are me, a cabinet maker cum architectural joiner based in Glasgow, with a PhD in archaeology. A love of the past and a passion for extending my range of unprofitable labour led me to try mixing my own linseed paints. To my wife's considerable surprise, the experiment was successful and the product looks financially viable. She'll be in charge soon.

We are me, a cabinet maker cum architectural joiner based in Glasgow, with a PhD in archaeology. A love of the past and a passion for extending my range of unprofitable labour led me to try mixing my own linseed paints. To my wife's considerable surprise, the experiment was successful and the product looks financially viable. She'll be in charge soon.Ross Samson or Valerie Lyon

0141 632 8681 or 07985 046827

28 Riverside Road, Glasgow G43 2EF